|

| |  |

|

Discretesignals

Ultimate Carjunky

/ Moderator

Apr 14, 2015, 6:52 PM

Post #1 of 5

(3219 views)

|

2005 Nissan Altima S 2.5L

RE4F04B

140 K miles

G, Kind of interested to see what you think about this one and any hints or tips to help diagnosing this.

Customer came in complaining of harsh shifting and check engine lamp. Code P0745 stored. PCS duty cycle at 0% and you can hear the trans pump whining. I didn't clear the code to see if it was an intermittent problem as of yet because there is a misfire code stored in there too.

I didn't really go in depth on diagnosing this one yet. I did take a voltage reading on the plug at the transaxle. This was after the vehicle cooled down. I started it up and the pump wasn't humming and the meter showed around 2.4 volts drop across the solenoid. I was using a fluke meter, so it is probably an average voltage of a pulse width modulated circuit. I will take the scope in tomorrow. Ohm checked the solenoid at the plug, with it disconnected, to battery ground and it showed around 2.9 ohms. Hooked up the power probe and activated the solenoid to see if it was clicking and it was. It was the end of the day and I wasn't going to stay late playing around with it, so I hit the homestead.

I got a feeling that this thing is failing when it gets hot. I'll take some captures and post them up tomorrow if you want to see what is going on when it goes tits up.

If you can thinking of anything else I should check I would greatly appreciate it. If you need any other data, i'll try to provide it

Since we volunteer our time and knowledge, we ask for you to please follow up when a problem is resolved.

(This post was edited by Discretesignals on Apr 14, 2015, 6:56 PM)

|

|

|  |

|

gsferraro

Veteran

Apr 15, 2015, 3:09 AM

Post #2 of 5

(3197 views)

|

One thing to check one this is the ground wire for the epc solenoid, sometimes they come loose in the eyelet under the valvebody bolt, creating a poor ground. lightly tug on the wire to see if it moves in the eyelet, if not its possible the solenoid is failing hot. Good info on your post. Gary

|

|

|  |

|

Discretesignals

Ultimate Carjunky

/ Moderator

Apr 15, 2015, 5:18 PM

Post #3 of 5

(3191 views)

|

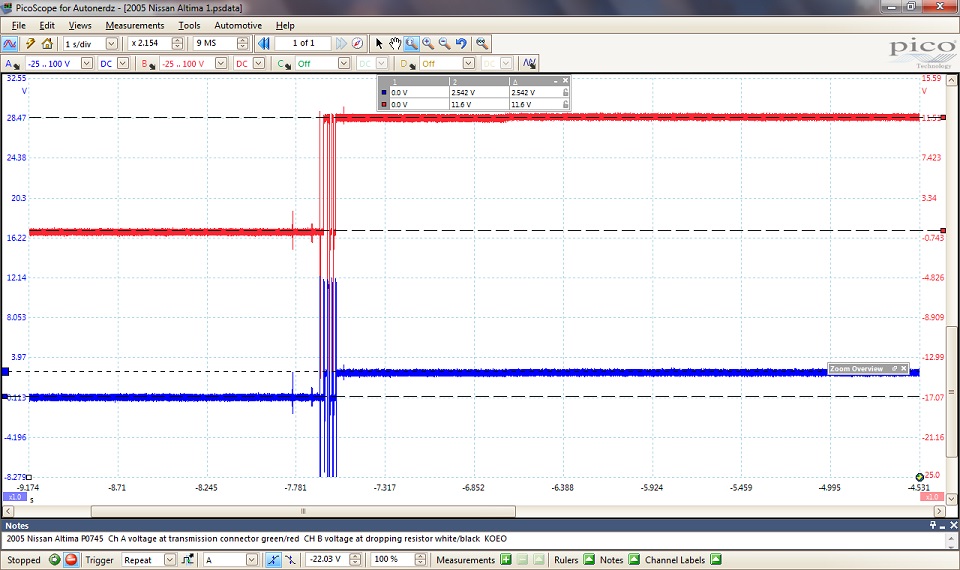

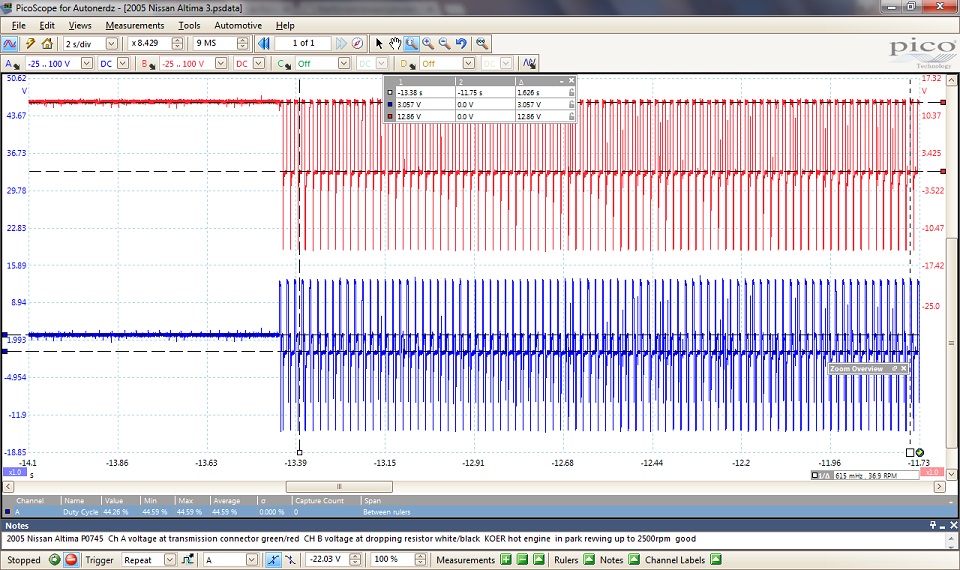

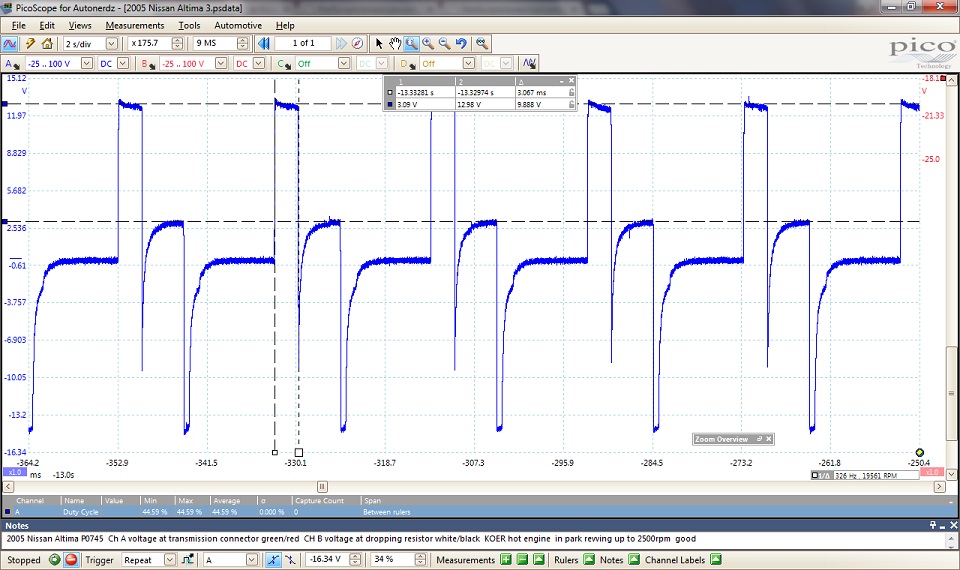

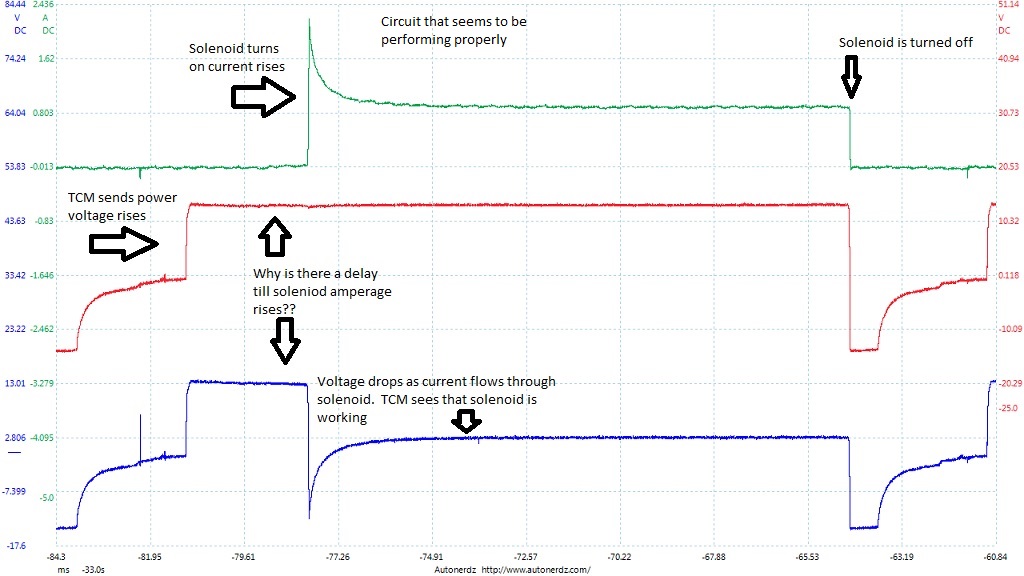

Well, Gary, decided to do some more electrical checks before tearing the pan off. I hooked up two scope channels. Channel A (blue) is back probed at the green/red wire at the transaxle connector. CH B is back probed on the white/black wire at the dropping resistor connector.

The way I believe this works is the solenoid is power side switched. The solenoid has low resistance, so a dropping resistor is used to drop the voltage and limit the cuurent as to not burn up the solenoid when it is being turned on all the time, 0% duty cycle on scanner. When the solenoid is at 0% duty cycle on scanner, line pressure is min. When the solenoid is turned off or has no power, the line pressure is max. Anything in between is duty cycled depending on engine speed, throttle position, gear selection, engine load, and etc.

The bad part is that I couldn't get it to act up and I couldn't drive the vehicle today because the LR hub bearing was getting ready to come apart and rear brakes were metal to metal. I could of hooked up a pressure gauge, but I'm sure it probably isn't mechanical.

I did notice that if I unplug the transaxle connector with the engine running, the line pressure would go high and the pump would whine. What is strange is that when I plugged it back in, the TCM would duty cycle the solenoid at about 17% for a few seconds and then it would go to 0% or full on. During the episode yesterday the TCM was commanding, or trying to command 0%, but it still had high line pressure.....hmmm. Today everything looks fine and it wouldn't act up. Probably fixed it when I disconnected the trans connector ohming out the solenoid. I'll get to drive it tomorrow and hopefully it will act up.

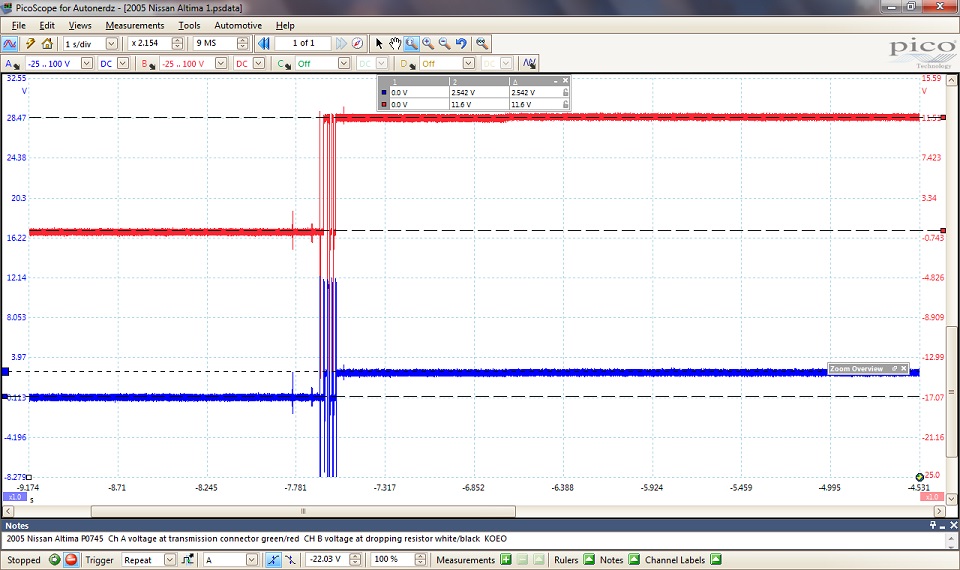

Here are some captures: ignition being turned on engine off. Total circuit drop 11.6V Voltage drop across solenoid 2.5 V

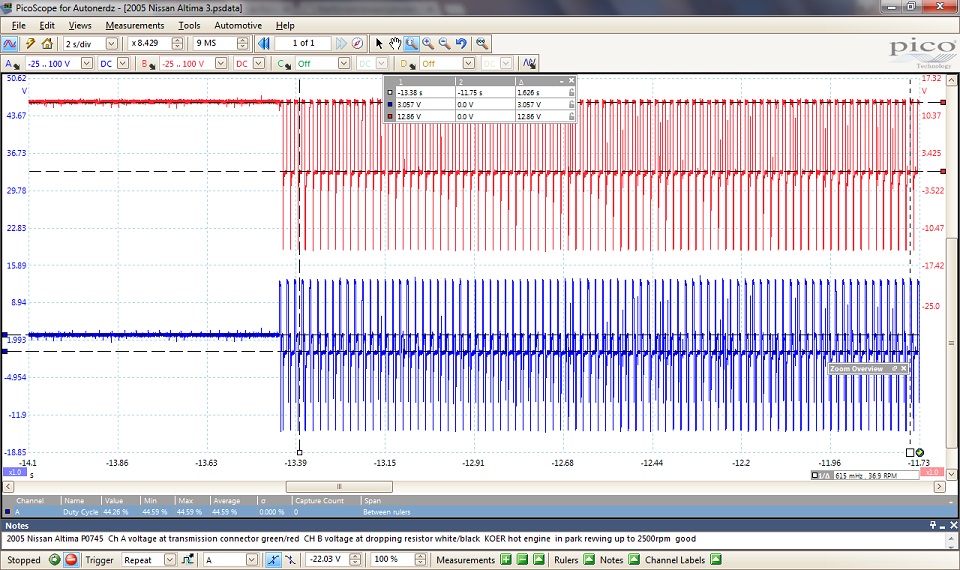

Another capture taken with engine idling and reving the engine to 2500 rpm. Around 44% duty cycle.

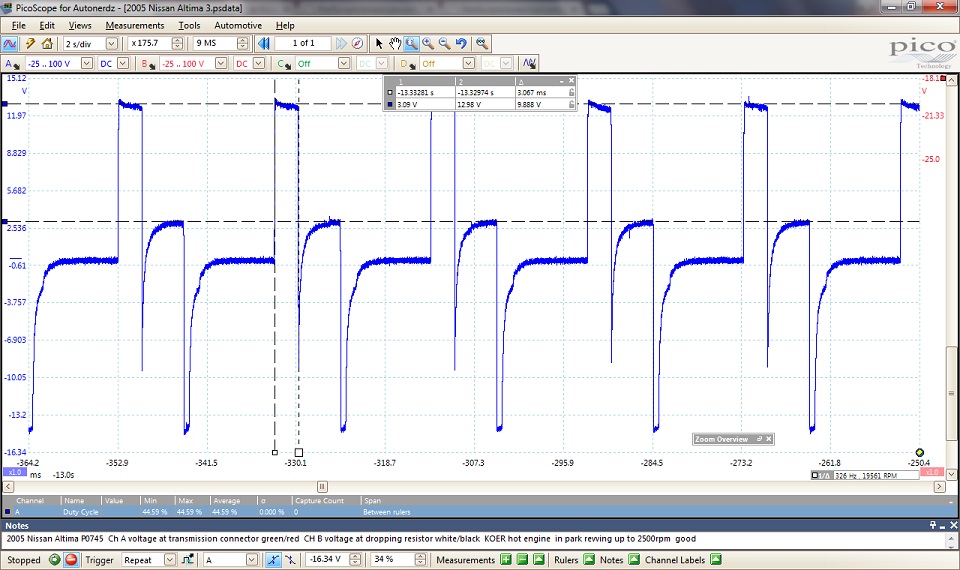

Close up of solenoid voltage being pulsed. Looks different than ground controlled solenoids.

Since we volunteer our time and knowledge, we ask for you to please follow up when a problem is resolved.

(This post was edited by Discretesignals on Apr 15, 2015, 5:53 PM)

|

|

|  |

|

Discretesignals

Ultimate Carjunky

/ Moderator

Apr 22, 2015, 5:21 PM

Post #4 of 5

(3129 views)

|

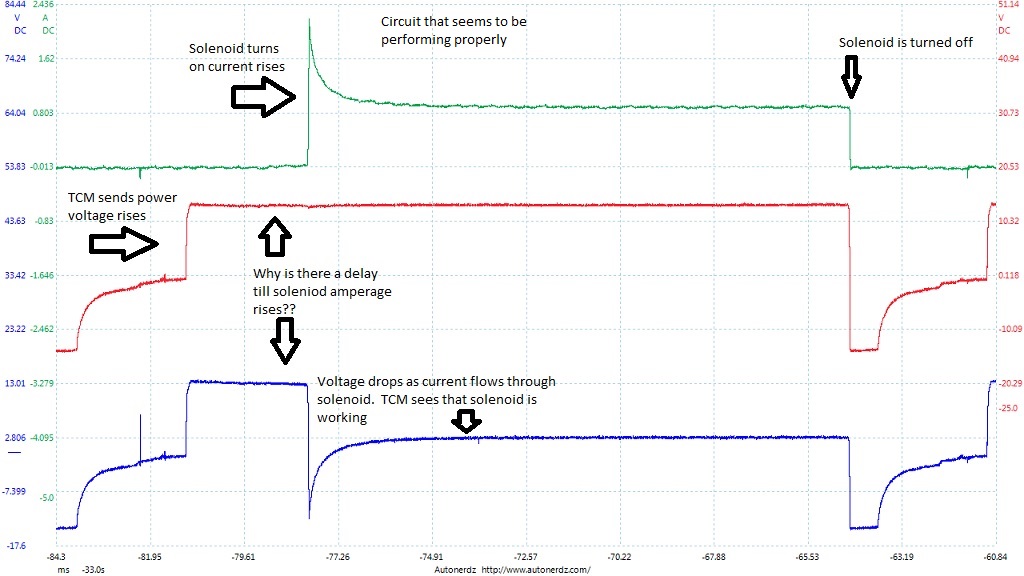

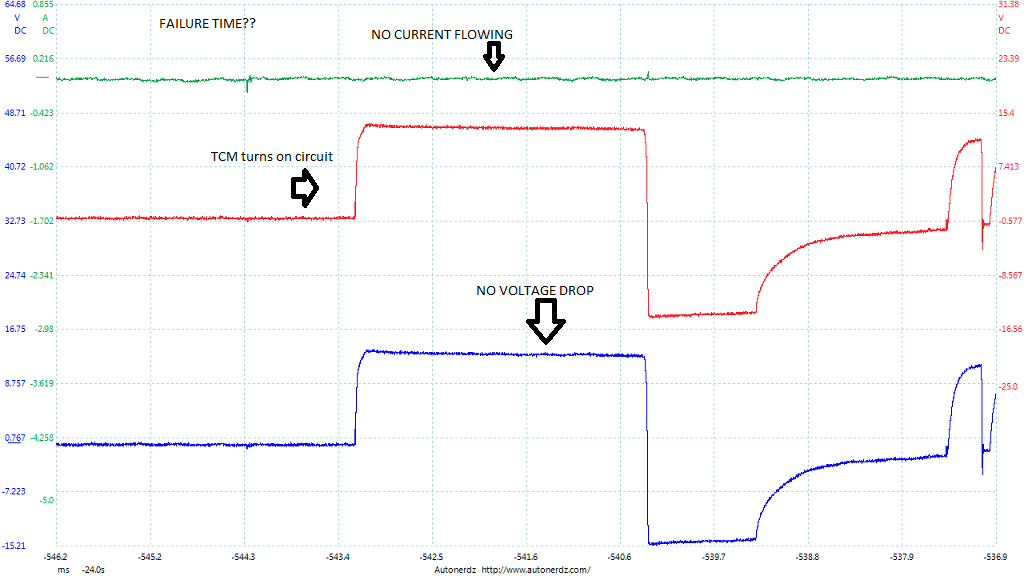

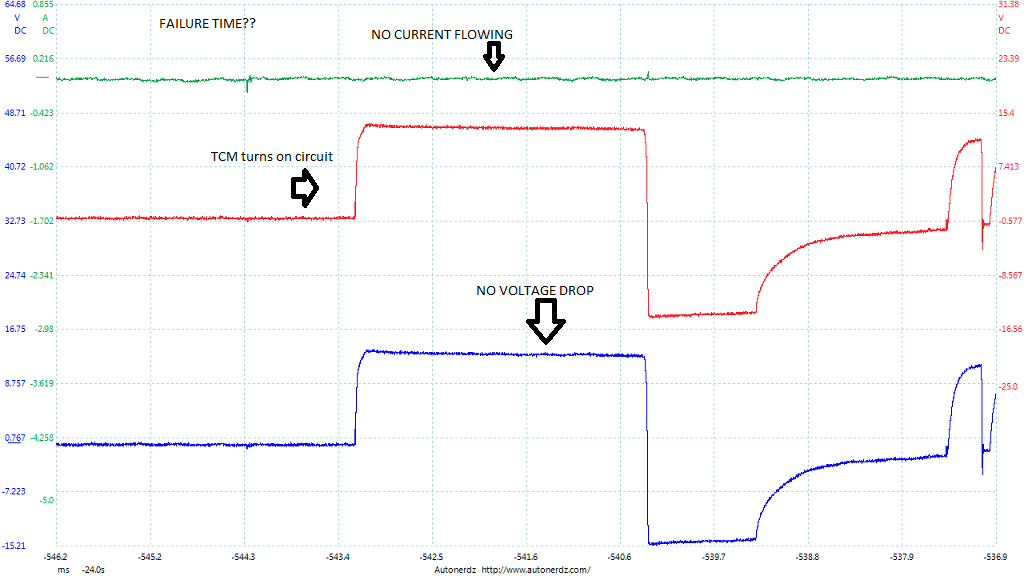

Just want to give an update. The customer has the car now till he comes back in for his scheduled appointment. I was able to catch the issue when it occurred and it looks to be behind the pan. Either a solenoid, ground, or harness inside the transaxle issue. During the failure the TCM sent power, but there was no voltage drop or current flow in the current. The TCM instantly flagged the code and defaulted.

The customer needed the vehicle, so they are going to come back for the final diagnosis.

Green trace is circuit current

Red trace is voltage drop of the entire circuit

Blue trace is voltage drop from trans connector to battery ground.

Some captures of the failure:

Since we volunteer our time and knowledge, we ask for you to please follow up when a problem is resolved.

(This post was edited by Discretesignals on Apr 22, 2015, 5:28 PM)

|

|

|  |

|

gsferraro

Veteran

Apr 23, 2015, 4:12 AM

Post #5 of 5

(3109 views)

|

When you drop the pan, more than likely the valvebody will have to come down, there maybe accumlators and springs that will fall out so watch out for that. Inside is a solenoid pack bolted to the valvebody, they are not serviced seperatly, the solenoids and harness are one. There are different solenoid packs, the difference is the lenght of the wire lead which sticks out of the trans(kinda like an external harness) some have long leads some plug in right at the trans, just match up the part before you install it. Gary

|

|

|  |

|