|

| |  |

|

gaz9012

New User

Jan 14, 2009, 3:48 AM

Post #1 of 6

(2441 views)

|

|

replacing rocker shaft

|

Sign In

|

|

Hi i own a first generation 1994 hyundia lantra 1.5 gls saloon M reg

My Rocker shaft broke when one of the end bolts became loose and worked its way under the shaft. Well thats where i found the bolt when i took the rocker cover off.

I am not mechanic, and only played with 2 stroke engines, so am a novice, unfortunetly i cant get to a mechanic or get one to me.

What i am asking is for the procedure to replacing the shaft. i know i need a torque wrench and feeler gadge for the job. If it helps it is the exshaust shaft that needs replacing.

the main thing i am not sure on what to do is how to turn the engine over to get the cams/values?? in there right places before i start to fix the shaft down.

and also how to tell when they are in the right place

unfortunetly in the uk, we are unable to get any kind of workshop manual for this modle, just getting the torque settings for the shaft took me over a week.

the original rocker shaft is still in place, so i am hoping to use the feeler gauge on the rockers to get the setting i need, i presume this is ok to do.

best regards, and waiting at his pc biting his finger nails in waiting for a responce lol :)

Gaz

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jan 14, 2009, 5:43 AM

Post #2 of 6

(2438 views)

|

|

Re: replacing rocker shaft

|

Sign In

|

|

Hi,

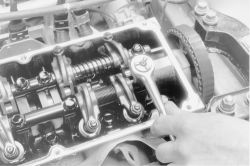

Having trouble finding good pics of just how this is layed out. Here's a 1.8 Hyundai rocker shaft if this look similar.....

To help me/us understand - Did one or more of the shaft holdown bolts just come loose or is it now stripped - torn/ruined threads?

If this looks real close please say so. We can suggest from there.

Adjustments may be fine when this is back at is should be. Can't know that and YES it should be checked with a feeler gauge when bolts are properly in place and torqued. No specs just yet - let's find out just what is broken first.

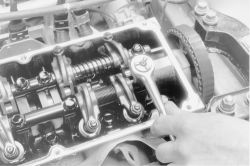

Another pic for reference if helpful.....

The link that discussed this at all is at......

http://www.autozone.com/...eId=0900c152800738d4

From that you might dig and find more info which is just what I'm doing right now.

Let us know just what has happened,

T

|

|

|  |

|

gaz9012

New User

Jan 14, 2009, 6:06 AM

Post #3 of 6

(2436 views)

|

|

Re: replacing rocker shaft

|

Sign In

|

|

Hi thank you so so much for getting back to me so quickly

The pics you show are perfect to what i see under my rocker cover.

the left hand end bold was under the shaft when i opened the cover, and the shaft had broken where the second bolt holds it down, only the one bolt had come loose. looking at the bolt, it looks like the thread had been squashed, rather than stripped. the bottom end of the bolt looks ok, and i can by hand re tightn the bolt up tp the point its squashed, so i think it has just come loose. thinking about it, for about a wekk beofore all this happened, i was pretty sure i could hear a small ticking/rattling noise in the car, maybe this is when the bolt had come loose and was being tossed about or the rocker was making the noise. it was very faint and only now and again. but when the shaft broke i was on the motoway traveling at ...er... 70mph lol. and there was a band noise and the car droped its speed down to 50 mph. i noticed that the noise got quieter at different reves, the noisest when i was pulling about at juntions, the higher the revers the quieter it become, but over all it was still a loud noise, enough for people to look and a few laugh lol.

i have managed to get the torque for the shaft 20-22 nm (could possibly 20-27) was hard to understand the guy on the phone.

and the cover is 1.5-2 nm

the feeler gauge setting is .25 on the exsaust side, and i think he said 1.5 o the intake, but i didn't write this down because i didn't need the info

just so you know, a friend who knows about cars is now traveling a long way down to fix it, if you wish to carry on looking for me, so others have a reference of it on your site am happy to carry on corrisponding. But if you are busy and need to help someone else, thats cool.

i wish i had found this site on christmas eve when the car decided to finally give in. but i will certainly use you again when i need some help

for point of reference, this page explains the replacing for my 1.5 engine, also shows the settings, thanks for linking such a great site

http://www.autozone.com/addVehicleId,1959502/initialAction,repairGuide/shopping/repairGuide.htm?pageId=0900c152800738d4

(This post was edited by gaz9012 on Jan 14, 2009, 6:16 AM)

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jan 14, 2009, 7:10 AM

Post #4 of 6

(2433 views)

|

|

Re: replacing rocker shaft

|

Sign In

|

|

OK: Can only guess at exact situation despite your description which is good. Threads of bolts may have survived well but the threaded hole is in question. It's possible that when the shaft failed it left the bolt(s) without resistance and they then could just wiggle out. New shaft is in order of course.

It may take some hands on assessment to know if the threaded holes are ok, might just need a tap run down them (grease taps if doing that in blind holes to catch the bits) or if they need what I know of as a "Heli'Coil" which is adding new threads to the hole made larger first by a drill then the coil used. That's a real judgement call and machine shops are best suited to deal with that.

Those are just some generic pics of what thread repair if need and the items look like. Just know you can get into a lot of trouble doing this stuff so make sure you know what you are up to if you need to do something like this.

Note on valve lash adjustment: It might be dang close when all parts are back in and snugged up properly to where it was before all this. Still worth checking all of them. When in doubt with valve/tappet/clearances it's generally better to err to a larger gap when in doubt as too small may hang a valve open and burn it in operation.

***********

Good luck. As they say "Measure Twice, Cut Once!"

Love your accent - It comes thru loud and clear

BTW - This is just a voluteer site with no strings attached. Just a few of us "blokes" sharing some gray matter with you,

T

|

|

|  |

|

gaz9012

New User

Jan 14, 2009, 7:51 AM

Post #5 of 6

(2426 views)

|

|

Re: replacing rocker shaft

|

Sign In

|

|

Well i just popped out to the car, just to check to see if the new rocker shaft i got would fit, and guess what, the guy has only sent me the wrong one!! numptie!! lol

as for the "hole" in question, i have got a new bolt and have tighten it up without the shaft in place, it tightens up further than i need it, so am guessing that the thread in the hole is fine.

I have noticed that 20-26nm isn't that tight for a bolt, so sueruly this could be the reason why the bolt has worked loose in the first place.

i really do feel that the thread in the hole is fine and that it had either came loose before the break or after. On the bolt that has the FLAT thread, because it looks squashed, the flat bit of thread is alot lower down the bolt, meaning that if it had been stripped from the hole then i wouldn't be able to be put a new bolt in it easerly.

Cheers for the heads up on my accent, forgot to say am dislexic and cant spell to say my life lol. Am shocked that the only guys i can find to help me, are in america lol in the uk, there is no manual for this car, any other no problem, but not this generation lol. even the link you gave me is for the second generation cars, but there are foot notes for my 1.5 liter lantra (vin K) i think, i assume they are using that reference from the first letter of my vin number.

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jan 14, 2009, 8:07 AM

Post #6 of 6

(2420 views)

|

|

Re: replacing rocker shaft

|

Sign In

|

|

Cool Beans - as they say in Boston - AKA "Beantown" -- I think you may have lucked out and only threads that are an issue are on the bolts which should be easy to fix or just get new.

There are products to help bolt - any threaded fastener from coming loose on their own. "Thread Locker" is one by name. You just put drops of that on the threads and it hardens up like "glued" in place. It may need to be torqued quickly so the measurement isn't confused if you tried something like that.

Be careful when dealing with alloy metals which simply won't be as strong as a steel bolt if that's how this is done. Mixing of metal types isn't a good idea in machines but they didn't ask me

You may luck out with this and be all set with just the proper rocker and bolts - hope so,

T

|

|

|  |

|