|

|

1975 F-250 Wiper Motor Shorted

|

|

|

|  |

|

cnlmgmt1

User

Jul 13, 2019, 10:21 PM

Post #1 of 19

(5919 views)

|

|

1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Aloha,

I've shorted out 2 re manufactured wiper motors AND also the original wiper motor that I thought was bad by following the Dorman bench test instructions. (3 wiper motors)

Please beat me up, but then could anyone please help me not screw up a 4th one.

I just bought a 1975 F-250 that I basically have to re-wire from scratch.

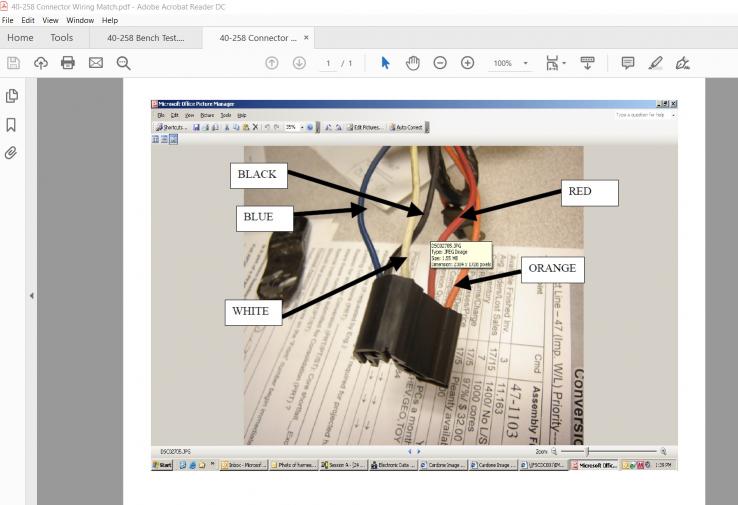

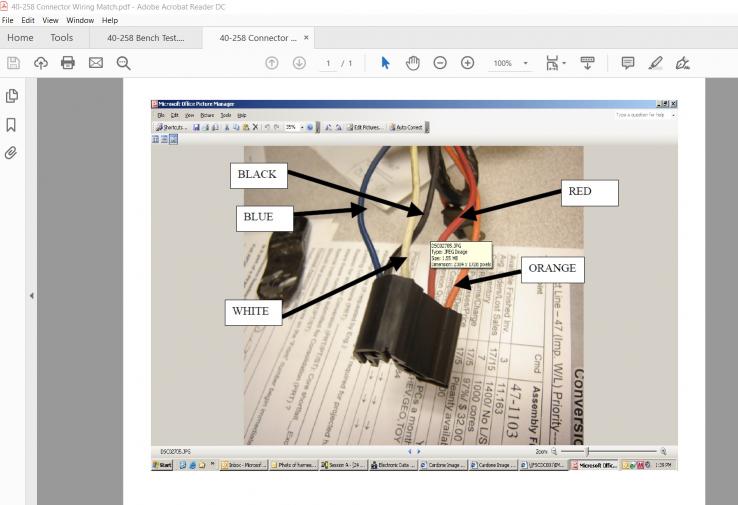

The wiper motor has 4 wires (Black, Red, White, Blue)

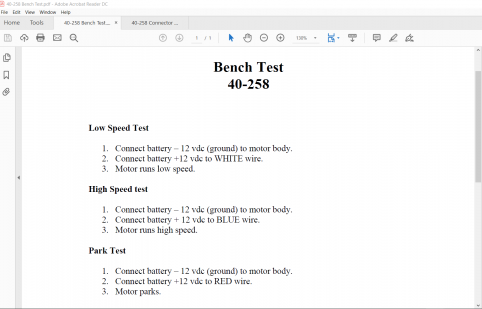

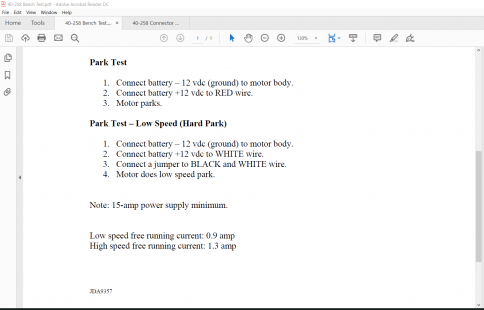

The Dorman bench test instructions are as follows. (Copied directly from the PDF that Dorman support emailed to me)

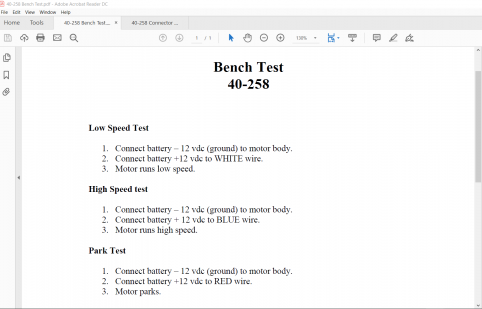

Bench Test

Dorman 40-258 Wiper Motor

Low Speed Test --- (Test Result: Motor ran for less than 1 sec then stopped. I've rendered 3 wiper motors unresponsive doing this)

1. Connect battery – 12 vdc (ground) to motor body.

2. Connect battery +12 vdc to WHITE wire.

3. Motor runs low speed.

High Speed test --- (Nothing happens)

1. Connect battery – 12 vdc (ground) to motor body.

2. Connect battery + 12 vdc to BLUE wire.

3. Motor runs high speed.

Park Test --- (I didn't get this far)

1. Connect battery – 12 vdc (ground) to motor body.

2. Connect battery +12 vdc to RED wire.

3. Motor parks.

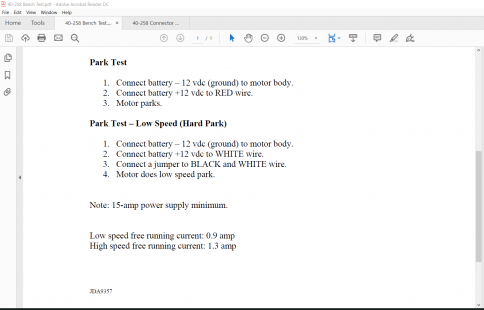

Park Test – Low Speed (Hard Park)

1. Connect battery – 12 vdc (ground) to motor body.

2. Connect battery +12 vdc to WHITE wire.

3. Connect a jumper to BLACK and WHITE wire.

4. Motor does low speed park.

Note: 15-amp power supply minimum.

Low speed free running current: 0.9 amp

High speed free running current: 1.3 amp

JDA9357

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 4:12 AM

Post #2 of 19

(5899 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Doesn't this truck have any original wiring or switches?

You can't do anything until you get hold of the original wiring circuit to see how the original circuit worked. I checked, my data base doesn't have one.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

cnlmgmt1

User

Jul 14, 2019, 11:32 AM

Post #3 of 19

(5888 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Hey, big Thanks!

I'll try to explain what's been done so far, as completely as I can.

I have a Ford certified cd of the shop manuals for that 1975 year F250.The Dorman instructions that were emailed to me (from Dorman) showed the same wires as the Ford CD. (White=slow, Blue=fast, Red=Park,Black=Ground)

Instructions from both Ford and Dorman:

1. Ground the wiper motor

So with the wiper motor laying on the bare metal inner fender shelf of the truck next to the battery, the Wiper Motor's Black Wire was then connected to the Negative Battery Terminal.

2. 12v from the battery to the wiper motor's white wire = Low So next was to just go ahead and connect 16ga wire lead from the + battery terminal to the white wire on the wiper motor to expect a low speed result.

Actual Result - The wiper motor twitched!

the impeller twitched with life

And then the motor immediately quits. Never to twitch again.

For this to be happening to more than one wiper motor, even when the motor was isolated away from the wiring harness and basically just going from the battery to the wiper motor?

Then I add the fact that the bench test instructions between Dorman and the Ford CD pretty much match each other. I just cant help but think I'm missing something incredibly simple that I've forgotten over the years.

Yes, there is what appears to be a factory wire harness and switches too on the truck. However, every wire in this old truck's harness (and I'm not exaggerating) has been poorly hand spliced with bare, hand twisted wires, with leads going off into "who knows" what rigging they've done to this dump truck. Plus, some of the untouched "chalky" and coroded wires in the harness were showing no continuity just from point 'a' to point 'b'. So I just wanted to get the new wiper motor working outside of the truck's harness including a new switch from Standard Mfg Co. and just go from there.

On my first attempt I had the both wiper motors laying next to each other, I swapped each of the 4 wires from the old motor's "harness connector" and then inserted the 4 wire wires (coming from the new wiper motor) into that old ford switch connector. I did this swapping process one wire at a time. This way the new wiper motor wires were reusing the original ford connector to perfectly insert into the new Standard mfg. switch.

The old ford harness connector that I was reusing to connect the new wiper motor to the new switch had a 5th wire that was Orange. So I assumed that this Orange wire would be the 12v coming in from the battery.

So with the new switch now connected to the White, Blue, Red & Black wires of the new wiper motor, as well as reusing the original ford connector to make the connection, I then applied 12v from the battery to the Orange wire.

These are the following results from connecting a new wiper motor with a new switch conducted outside

of the truck's wiring harness:

Off position : Wiper motor remained 'off'

Position 1: Wiper motor actually starts for just a split second and then stops.

BUT ALSO during this event there is a constant clicking sound coming from the new switch.

The sound coming from the switch continues until I return the switch to the 'off' position.

Position 2: Same result as position 1

Overall result: new wiper motor never ran again after trying the motor a couple times in those various positions. When the motor did show life, it was only for a split second --------------------------------------------

Next, I put the old leads from the old wiper motor back into the old ford switch connector so I wouldn't get things mixed up.

Here's what happened when I received the second new wiper motor:- I sat on my hands until I received a Wiring pdf directly from the new motor's manufacturer on "bench testing" their new motor. (Dorman)

- Then I followed their bench test instructions using the truck's battery connected directly to the wiper motor without going through the new switch.

The black wire of the new wiper motor was connected to the battery negative, and the white wire of the new wiper motor was touched to the battery's 12v + positive post.

And the result was the same "split second response", followed by no further life by the wiper motor ever again.

-------------------------------------

Whatever possessed me to try the same bench test on the old wiper motor? I don't know. I guess I was doubting the quality of the second new motor (rebuilt wiper motor) over the possibility that the testing process was going wrong somewhere.

And yep, I think I blew up the original motor using this bench test which and the motor might have been perfectly fine with the original problem lost somewhere in all those hand spliced harness wires.

So now I have another new wiper motor on the way again.I wont take it out of the box this time until I'm sure I know what's going on.

Any help is sincerely appreciated.

Here are screen shots of :1. the old motor and the new motor,

2. The new switch

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 11:44 AM

Post #4 of 19

(5886 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

That is not a Dorman motor you bought. That A1 Cardone. Why are you getting instructions from Dorman?

I still want to see a wiring diagram from the manufacturer.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

cnlmgmt1

User

Jul 14, 2019, 11:48 AM

Post #5 of 19

(5882 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

SORRY I don't know why I've been saying Dorman. I'm so very sorry here.------------------------------

The bench test and the wiring diagram from Cardone are pdf's.Here are screen shots of the pdf's.

The email where these pdf's came from is:Technical Services Technician | Cardone Industries - USA

(This post was edited by cnlmgmt1 on Jul 14, 2019, 12:10 PM)

|

|

|  |

|

cnlmgmt1

User

Jul 14, 2019, 12:18 PM

Post #6 of 19

(5872 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 12:20 PM

Post #7 of 19

(5872 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

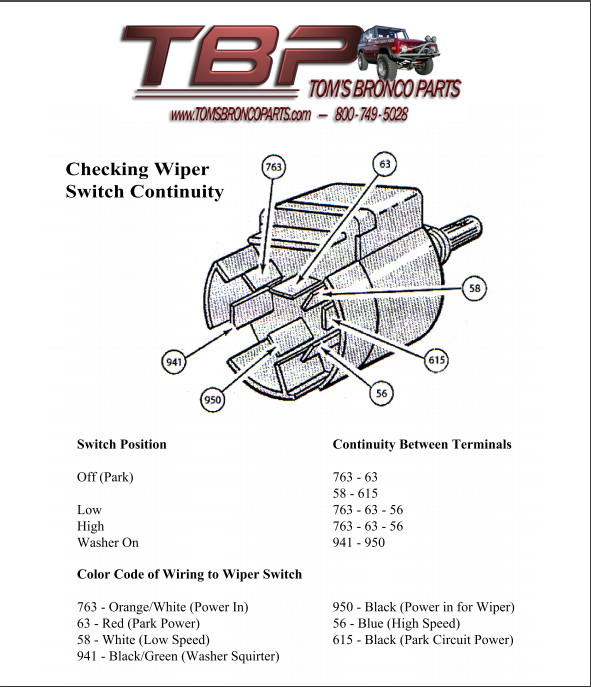

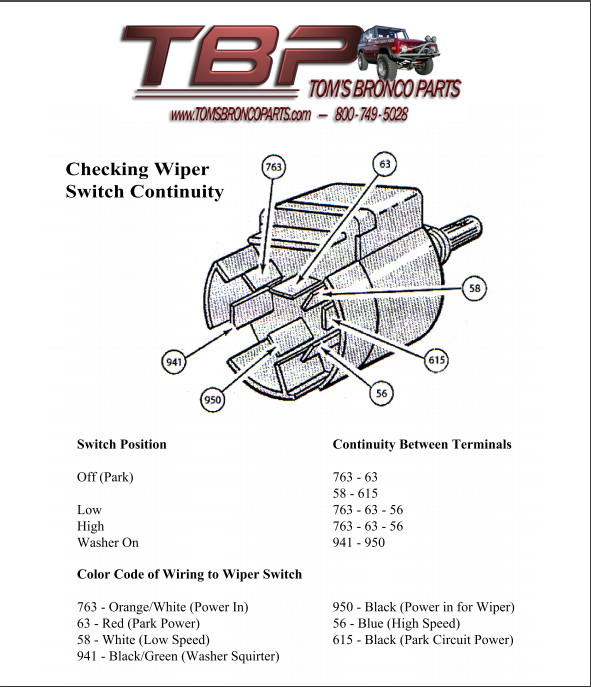

These should help

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

(This post was edited by Hammer Time on Jul 14, 2019, 12:22 PM)

|

|

|  |

|

cnlmgmt1

User

Jul 14, 2019, 12:37 PM

Post #8 of 19

(5862 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

This is beautiful!!

The second diagram you show is exactly what I want to do. Exactly!A simple On-off-On switch. I don't care about park/stop at this point. lol.

Question: Can you tell me what size/amp fuse I should use in your on-off-on diag?

And thank you!!!

By the way, I've sent the same problem description that I typed for you in this thread (incl pictures) along with my response email to Cardone support.

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 12:42 PM

Post #9 of 19

(5858 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

You have to worry about park. It needs to be wired exactly as you see it if you don't want to fry another motor. You need a 3 way switch that can handle at least 20 amps. Use a 20 amp fuse.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

cnlmgmt1

User

Jul 14, 2019, 12:52 PM

Post #10 of 19

(5852 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Wait a second! This might be it!

In your bottom "3-wire wiper motor" diagram (I have a 4 wire motor) you show that the black wire on the motor to be the 12v positive wire. Would that be the same in my situation?????

If the black wire on my motor is truly the 12v positive line then this could be my problem.

I have been using the wiper motor's black wire as the motor's ground wire and therefore connected it directly to the - negative battery terminal and then the positive battery voltage was connected to the white wire (or slow speed wire) of the wiper motor.

I will certainly ask Cardone to clarify weather the black wire on my 4wire motor is the positve wire. Because the bench test calls for 12v to the white or blue wires.

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 12:54 PM

Post #11 of 19

(5850 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Wild but real maybe that semi showed in Hammer's last pic. The body of the metal of motor should ground itself not just a wire or will go nuts, leave wipers up, not park and just be whacked. Not mentioned for a lousy contact when mounted should have that. One of those three should NOT be isolated by rubber if so, some used a band of metal to bolt back to firewall metal known clean. Just painting it could fubar this. Just thinking? Shouldn't hurt a thing to ground motor metal to metal or ground of test battery power,

T

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 12:57 PM

Post #12 of 19

(5849 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

You have the right switch for it. Why don't you just use the other diagram and wire it the right way instead of Mickey Mousing it with a toggle switch.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

cnlmgmt1

User

Jul 14, 2019, 1:40 PM

Post #13 of 19

(5843 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Yes,

I did use the the correct switch the first time around. (See my earlier post)

When I used the right replacement switch (and carefully swapped out each wire from the old wiper motor connector one by one) along with the new motor in the bench test there was a clicking sound coming from inside the switch. The motor ran for a fraction of a second but then stopped, while the new switch continued to make that clicking sound until I returned it to the off position. The result of that was the first rebuilt motor no longer would respond at all to any 12v connection at all.

Only after that failure using the correct switch did I try the simple bench test directly connecting the second rebuilt motor's white wire to the battery after attaching the black wire to ground. And I got the same dead motor result after a fraction of a second of motor activity. Same scenario as using doing the bench test with the new switch.

And like an idiot I went and followed the same Cardone bench test instructions to test the original motor and probably ruined a perfectly good motor that was probably fine in the first place because it reacted in the same way as the 2 rebuilt ones.

(This post was edited by cnlmgmt1 on Jul 14, 2019, 1:42 PM)

|

|

|  |

|

Double J

Veteran

/ Moderator

Jul 14, 2019, 7:56 PM

Post #14 of 19

(5831 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Their Instructions don't tell you to connect the Black wire to Ground,

They state to connect battery neg(ground) to the Motor Body, not the black wire.

Excerpt from what you posted.....

1. Connect battery – 12 vdc (ground) to motor body.

2. Connect battery +12 vdc to WHITE wire.

3. Motor runs low speed.

High Speed test --- (Nothing happens)

1. Connect battery – 12 vdc (ground) to motor body.

2. Connect battery + 12 vdc to BLUE wire.

3. Motor runs high speed.

so they're not wrong, you made an assumption that the black wire was ground.

|

|

|  |

|

Tom Greenleaf

Ultimate Carjunky

/ Moderator

Jul 14, 2019, 11:13 PM

Post #15 of 19

(5814 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Spot on! Was my hunch - it's in there just not said in plain English. Body of motor must go to ground (firewall) the mounts are isolated for shock + vibration. That ground wire with spurs on it you would put a bolt thru such that the 'ears' of the 3 mounts, 1 of them grounds the whole show all at once.

You'd see that taking the old one off. Now it's all painted up new looking isn't cutting it - right?

See barely the rubber isolation in old one...……

>

See the wire eyelet end

>

See the diagram from HT, lower right is the body of the motor

>

Aloha,

Now you have wipers! Double J it was hidden in all this all along, you found it I was thinking that also. Aloha!

Tom

|

|

|  |

|

cnlmgmt1

User

Jul 15, 2019, 8:32 PM

Post #16 of 19

(5797 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

"so they're not wrong, you made an assumption that the black wire was ground."

THIS assumption of mine is exactly what I'm afraid of.

I really think your above statement is correct.

Anyway, I have a call in to Cardone support and expect a "call back" tomorrow.

I thought by laying the new motor on the bare metal of the fender would be a good body ground but probably not I suppose.And the second important thing you guys have pointed out is that black wire on the motor (not the switch). I'll be sure to ask them what is the purpose of the black wire as well because if it's not a ground wire then I shouldn't be connecting it to the negative battery terminal.

My new wiper switch is a Standard DS700.

I also have a call in to Standard for a diagram of the terminals for that switch.

I realize that there is a picture in this thread from Tom's Bronco but at this point I don't want to take any chances. lolI'll let Standard support verify the terminals on their switch.

Thanks everyone.I promise to share what I find out after talking to Cardone support.

(This post was edited by cnlmgmt1 on Jul 15, 2019, 8:44 PM)

|

|

|  |

|

cnlmgmt1

User

Jul 16, 2019, 5:53 PM

Post #17 of 19

(5762 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

UPDATE:

Guys,

Remember in my first post how I was kicking myself because I believed I was forgetting something very basic?

it was PAINT as well as my wrong assumption of the black wire.The black wire AND the red wire are part of the "park/off" feature.

The wire info came from Cardone support AFTER I had already identified the ground problem based on your observations recommendations and got it running.

Based on your help, I took a wire brush and brushed off the paint on the 3 points of the motor where it makes contact with the body of the truck.After removing the black paint to those points, I connected the body of the motor to the negative battery terminal and touched the white wire to the positive battery terminal, and this new motor that I thought I had shorted out began to operate normally. Performing the same operation using the blue wire allowed the new motor to run at high speed!This tells me the 1st new wiper motor would probably have also worked fine just like this new one one did today.

I also performed the same test with the original rusty old motor and the it worked as well! Much slower than the new motor, but it worked!

Then I called Cardone support and learned the purpose for the wiper motor's black wire.

----------

NEXT:-----------

I reconnected ALL 4 wires from the new wiper motor to the new switch, and with the new wiper motor body being grounded properly this time, the motor worked, but only for several seconds before stopping as if to simulate a "park condition". This was interesting since I never disconnected the switch from the 12v positive terminal while it was running for those 3 seconds. Also, I never removed the switche's black ground wire from the negative battery terminal. So I don't understand why it would stop after running fine for about 3 seconds.

So my next stop is for me to contact the switch manufacturer to identify precisely what the contact blades on the switch are.

Guys I've really appreciated all your help here. Thanks for being so patient and helpful to a someone that hasn't done any automotive work in probably 20 years.

Aloha and Thank you so much!!!

|

|

|  |

|

Hammer Time

Ultimate Carjunky

/ Moderator

Jul 16, 2019, 6:10 PM

Post #18 of 19

(5758 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Why don't you stop with all the jumping and testing and just install it permanently and wire it to the switch the right way.

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~

We offer help in answering questions, clarifying things or giving advice but we are not a substitute for an on-site inspection by a professional.

|

|

|  |

|

cnlmgmt1

User

Jul 16, 2019, 6:46 PM

Post #19 of 19

(5754 views)

|

|

Re: 1975 F-250 Wiper Motor Shorted

|

Sign In

|

|

Because

- there is no voltage going to the switch the right way,

- because the fuse box is physically broken in 2 places and the fuse contacts are rusted and falling apart so I have to re-do all that.

- because the black plastic of the old wiper switch fell apart in my hand when trying to remove the wiper motor connector from it.

- because there is no continuity in many of the chalky wires in the harness- because there are more hand twisted, bare wire splices in that wiper circuit than I can shake a stick at.

- and with the old wiper motor taken out, also out went the original ford harness connector the wires fit into. And because the new cardone motor does not come pre-wired with a ford harness connector for the red, white, blue, and black wires. (Note: The new motor only comes with pre-crimped female blade connectors, so I have to remove the wires of the old motor from the old ford harness connector so that I can reuse that connector for the wires on the new motor.) I'm doing all this so that I can connect to the switch the right way. But when I connect to the switch the right way the motor seems go into a "park condition" within 3 seconds, which is why I want to verify with Standard inc. that the terminals on their switch match what the Ford shop manual is calling for.

Because of the unreliable wiring harness and unreliable switches & components of this old dump truck, I just wanted to make sure I had a "working baseline" to go on before putting it all back under the dash, so I wouldn't find myself chasing down a whole lot potentially unnecessary issues.

I'm sure there might have been an easier way, but this was the only approach I could think of.

(This post was edited by cnlmgmt1 on Jul 16, 2019, 6:58 PM)

|

|

|  |

| |  |

|